Forge is ideal for large prints, but sometimes you want to print bigger than Forge's build plate area. How do you make such project work?

Forge is powered by the all-new Vlare Core controller with features that will make printing easier, faster, and more accurate. Among other things, its auto-support feature makes adding supports easier.

A Forge user shared the helmet he printed and welded, as shown below. The file was designed by Yosh Studios, you can see more of his designs on his Instagram @yosh__studios and click here to view his Patreon

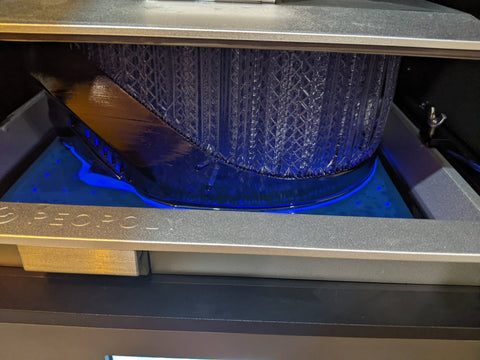

Printing process:

The helmet was printed in 4 parts, the main helmet was 2 prints and the back veil in 2 pieces.

2 print runs on Forge using Vlare light auto supports and Neo settings. One print 9hrs the other print was 13hrs. Approx 1.5kg of Siraya Tech Simple smoky black resin.

(Vlare auto support setting pictures)

Resin Welding:

Resin welded using a syringe and UV flashlight. The model was in 2 pieces. He cut each in half then added alignment tabs and slots in Microsoft 3D builder.

Model sanded from 150grit to 240 grit then wet sanded from 320 grit to 1000 grit (320/400/600/800/1000). Primer and black paint then resanded at 600 grit. 2 more coats of black paint. Resanded at 600 grit then 2 coats clear coat.

Red vent inserts on the side are 3d printed in PLA and the visor is made of FDM printed frame and red lighting gel for the lens. Lens hot glued from inside for easy replacement. Used packing foam to line the interior to perfect fit on its head.